product categories

Certifications

Address: No. 489, Hongtai 6th Road, Xiaoshan Economic Development Zone, Hangzhou, Zhejiang, China.

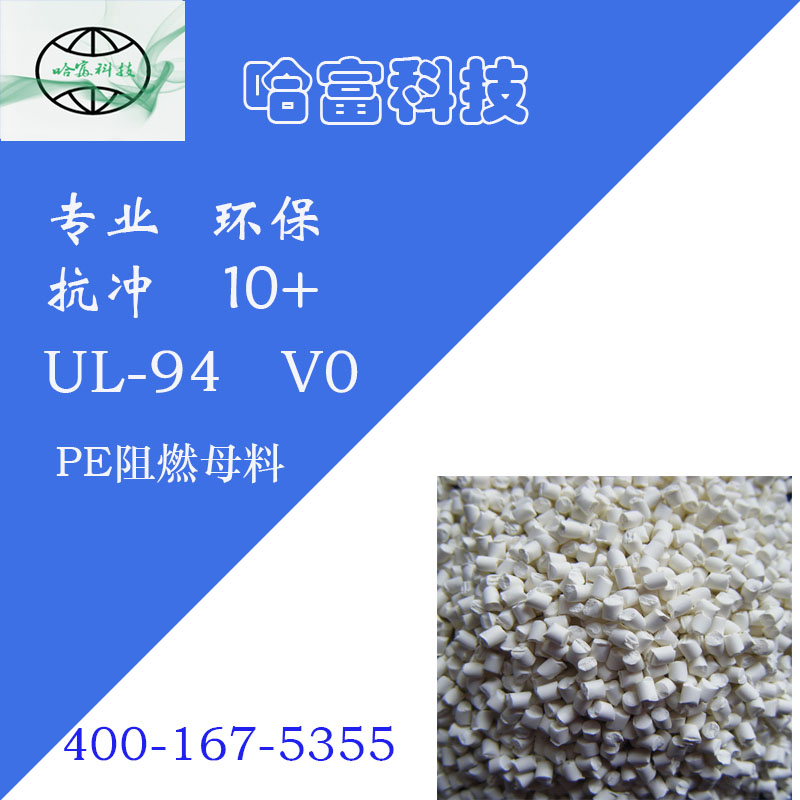

PE Flame Retardant Master batch JW-01-FR5010M

PE Flame Retardant Master batch is an additive type of flame retardant master batch. It has good processing fluidity, excellent thermal stability and light stability. It can achieve the flame retardant effect without the need to add antimony trioxide. It can be directly injection molded into finished products after being blended with virgin PE materials. It effectively overcomes the shortcomings of traditional flame retardants, such as high density, high addition cost, serious deterioration of various physical properties of products, poor compatibility with resins, easy precipitation, frosting and whitening due to large addition amounts. It is one of the flame retardant products for PE on the current market. This product fully complies with the EU environmental protection standards (RoHS). PE Flame Retardant Master batch is mainly used for flame retardancy of PE sheets, PE pipes, PE boards, wire and cable, PE blown films, wire drawing, etc.

PE Flame Retardant Master batch

I. Introduction

PE Flame Retardant Master batch is an additive type of flame retardant master batch. It has good processing fluidity, excellent thermal stability and light stability. It can achieve the flame retardant effect without the need to add antimony trioxide. It can be directly injection molded into finished products after being blended with virgin PE materials. It effectively overcomes the shortcomings of traditional flame retardants, such as high density, high addition cost, serious deterioration of various physical properties of products, poor compatibility with resins, easy precipitation, frosting and whitening due to large addition amounts. It is one of the flame retardant products for PE on the current market. This product fully complies with the EU environmental protection standards (RoHS). PE Flame Retardant Master batch is mainly used for flame retardancy of PE sheets, PE pipes, PE boards, wire and cable, PE blown films, wire drawing, etc.

II. Suggestions for Use and Precautions

A. Appropriate processing temperatures: LDPE: (180 - 200°C); HDPE: (190 - 220°C).

B. Adding 15 - 20% of talc powder appropriately can reduce costs and play a reinforcing role. (Note: The addition amount shall not exceed 20%. The effect of talc powder masterbatch is better. Barium sulfate must not be added, otherwise the flame retardant effect will be lost!)

C. The melting points of different virgin PE materials are different, so the addition proportion of the flame retardant will also be slightly different. When the addition amount exceeds the recommended proportion, the larger the addition amount, the worse the flame retardant effect will be. (Note: It is required to be virgin PE materials, not waste or recycled materials.)

III.Product Characteristics

1.PE Flame Retardant Master batch is processed with environmentally friendly raw materials through polymer treatment, improving its compatibility, dispersibility, weather resistance and other excellent properties.

2.The addition amount of master batch is small, but its flame retardant performance is strong.

3.It has a high whiteness and has no impact on the color and other properties of products.

4.PE Flame Retardant Master batch complies with the EU environmental protection requirements and can provide SGS test reports.

IV.Applications

1.Wire Drawing Grade:

PE Safety Net Flame Retardant Masterbatch: With a small addition amount, strong flame retardant performance, no wire breakage and no net clogging.

2.Extrusion Grade:

PE Waterproof Roll Flame Retardant Masterbatch: With good weather resistance, strong anti-ultraviolet ability, no precipitation and good flame retardant dispersibility.

PE Film Flame Retardant Masterbatch: With good dispersibility, no impact on the basic properties such as film transparency and coloring power, good compatibility and being of an environmental protection grade.

PE Corrugated Pipe Flame Retardant Masterbatch: With a small addition amount, excellent flame retardant dispersibility, resistance to high and low temperatures, no precipitation and being of an environmental protection grade.

PE Cable Pipe Flame Retardant Masterbatch: With a small addition amount, excellent flame retardant dispersibility, resistance to high and low temperatures, no precipitation.

3.Others:

PE Polyethylene Artificial Turf Flame Retardant Masterbatch: With good flame retardant performance, a small addition amount and excellent compatibility.

V. Instructions for Use

1.This product is packaged in 25kg flame retardant special bags, stored in a sealed manner in a cool and ventilated place. The storage period is one year. Transport it as non-dangerous goods.

2.Since the product performance varies with different processes and each user has different standards, it is necessary to understand the adaptability and performance of the product in advance in specific production applications. We can help users clearly understand the product and provide comprehensive technical support and after-sales service through telephone or email.

3.The environmental protection grade products have passed the certifications of SGS, RoHS standards and UL system.